B613 Glue

Keywords: industrial cotton paper tape, PET double-sided tape, flame retardant tape, double-sided PE foam tape

Category:

Products

Other

We will tailor-madetechnology leading solutions for customers,so that customers can get satisfactory adhesive series products.At thesame time,we will pay attention to the change of customer application environment

Contact:

Product Details

Product name:

B613 Glue

Product Description:

A. This product is a two-component oil -based pressure sensitive adhesive

B. This product can be used to produce high temperature industrial double-sided adhesive, which temperature resistance is more than 100 ℃ and anti surface rebound performance is good, adhesion of various materials have good performance

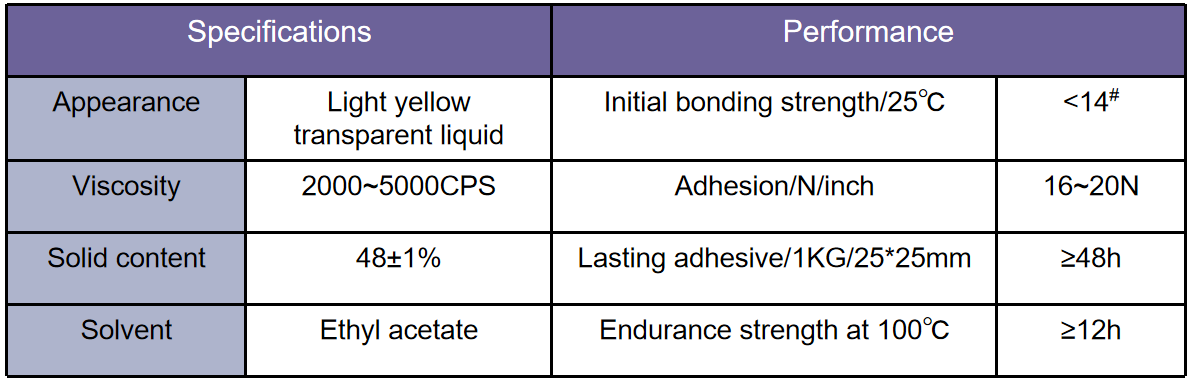

Performance Of Conditions:

Test formula: B613 glue + H261 crosslinker=100:1.0

Release paper: The shallow coating adhesion rate of release paper ≥ 95%

Base material: 25μm PET film

Glue amount: Apply 35μm dry adhesive on one side

Coating method:

Apply glue on 25μm PET substrate and dry at 100℃ for 3 minutes, then, cover the adhesive surface with release paper for testing.

Ripening process:

Put it at 55℃ for 15 hours or at room temperature for more than 7 days, and then do the performance test.

★The above values are our laboratory test results, only for reference.

★Users can adjust the amount of crosslinking agent according to the actual needs to achieve the desired effect.

Product keywords: metal working oil/fluid, rust prevention oil/fluid, stretching oil/fluid, cleaning agent, acid pickling agent, phosphating/passivation agent, paint mist coagulant

Usage tips: The establishment of adhesive strength depends on the infiltration of the adhesive and the surface. Increasing pressure helps to form better surface contact and improve bonding strength. The bonding surface must be kept clean and dry to achieve the best bonding effect. Typical surface cleaning agents are isopropanol solution * or heptane. The ideal temperature range for adhesive tape adhesion is 70 ° F to 100 ° F (21 ° C to 38 ° C) on the surface of the object. When used for the first time, it is not recommended to adhere at temperatures below 50 ° F (10 ° C), as the adhesive will become too hard to achieve good adhesion. However, after proper use, satisfactory bonding results can be achieved even in low temperature environments.

*Note: When using solvents, ensure to follow the precautions and usage guidelines provided by the manufacturer.

Shelf life: Under initial packaging conditions, stored at 70 ˚ At a temperature of F (21 ° C) and 50% relative humidity, its shelf life is 18 months from the date of manufacture.

上一页

无

下一页

Recommended products

Provide you with a solution and be prepared for your choice